The fundamental architecture of DynaKinetic™ rotary engines, compressors, pumps, and gas motors is a ground-breaking step forward for internal combustion engine, compressor, pump, and exhaust heat recovery technology.

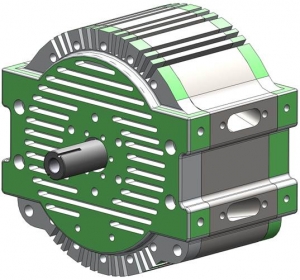

The sliding cylindrical “dead weight” pistons used in traditional piston engines, compressors, and pumps are replaced by “hinged” pivot pistons which are much more efficient in converting combustion to rotational energy and delivering it to the drive train or in pressurizing and flowing gases and liquids. If you correlate the piston to a concrete slab and think about how one would start lifting the slab, the common slab lifting method of 99%+ of people would be to raise one edge from the ground first rather than to “dead lift” the slab. This is the pivot piston movement approach in the DynaKinetic™ rotary technology which also dramatically reduces reciprocating weight and adds leverage. The rotating and wobbling tri-lobular rotor placed inside a figure-8 housing used in traditional Wankel (Mazda) engines is replaced with a perfectly circular rotor in a perfectly circular housing so rolling apex seals, center pinched-off combustion chambers, and small crank offset created leverage are eliminated.

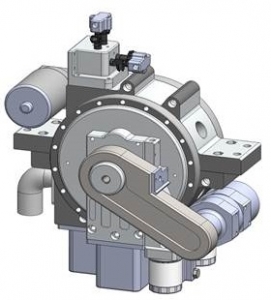

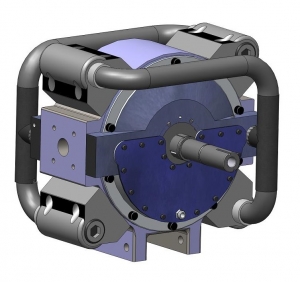

The product is internally cylindrical and is easily scalable in displacement by simply increasing diameter and/or axial length. Additional chambers can be added as diameter increases. Engines, compressors, pumps, or gas motors can also be connected end-to-end or stacked to increase displacement, pressure, or flow.

HOW THE DYNAKINETIC™ ENGINE WORKS

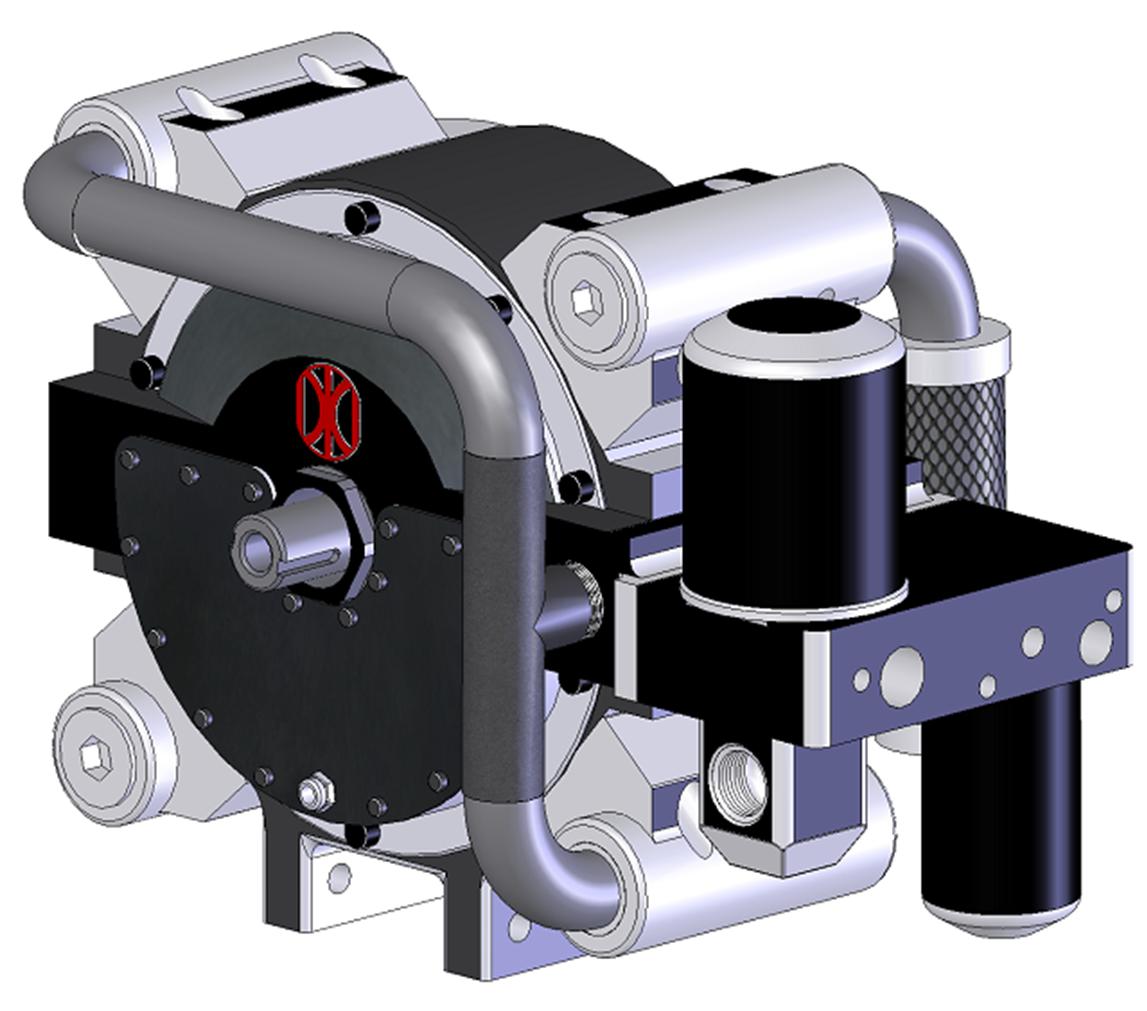

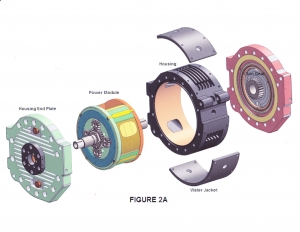

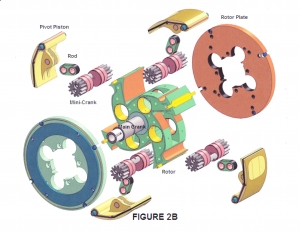

In Figure 1A the inventory of important parts are shown. There is a roughly an “X” shaped framework (like a twisted Ninja throwing star) called the rotor with its integrally connected rotor plates (not shown in Figure 1A but shown in Figure 2A), four planetary gears with journals at the ends of the mini-crankshafts on both sides, four solid connecting rods, and four hinged pivot pistons that make up the 13 moving parts. The outer circle, called the housing and sleeve, and the innermost sun gears along with their housing plates (not shown in Figure 1A but shown in Figure 2A) are all non-moving parts.

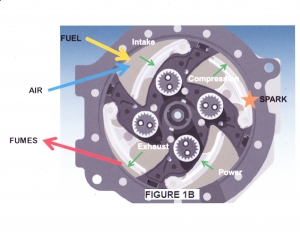

Figure 1B shows the 4 cycles including fuel and spark when the engine is configured to run in a spark ignited Otto cycle mode with port injection (it should be noted that the engine can run with a Diesel cycle compression ignition and with direct injection – this simply is not shown). At the upper left of Figure 1B (9 to 12 o’clock) air and fuel flows into the cavity between the housing and the retracted pivot piston and starts the intake stroke.

As the rotor turns clockwise through the compression stroke at the upper right of Figure 1B (12 to 3 o’clock), the pivot piston is moved out from the connecting rod that moved as the mini-crankshaft’s planet gears push the connecting rod to the furthest point out. Now the fuel mix is ready for ignition.

At the bottom right of Figure 1B (3 to 6 o’clock), the energy from the burning fuel’s released expanding gas pressure and heat pushes the pivot piston back to the centerline. The energy flows through the connecting rod into the mini-crankshaft whose planet gears try to transmit it to the center stationary sun gear (shown in Figure 2A). But, the force of the energy is applied to the rotating mass of moving parts, called the power module, instead. When the fuel charge goes off, the pivot piston and connecting rod are moving inward turning the mini-crankshaft journal in a half rotation pulling the rotor and all the moving parts a quarter turn around. That’s the power stroke.

At the bottom left of Figure 1B (6 to 9 o’clock), momentum as well as the following chamber’s power stroke takes the rotor another quarter turn as the mini-crankshaft has turned another half turn and pushed the pivot piston fully out again to complete the exhaust stroke.

A main crankshaft is fixed to the rotor center. All chambers move thru all four cycles (intake, compression, power, and exhaust) with each rotor revolution. This means that the main crank turns at half the rotational speed of a traditional 4-cycle piston engine!

The combustion chamber is almost triangular in shape but with a cylindrical shape at its top. Four mini-crankshafts turn in the rotor that spins a main crankshaft that also turns within the simple circular housing. The housing acts as both the block and the head.

Figure 2A & 2B clarify the connecting rod and crankshaft designs and makes the energy flow and motion more clear. The rotor and its two rotor plate end caps are integrally rotating parts and simplify the pivot piston sealing.

The rotating rotor plate end caps greatly reduce the pivot piston seal wear. The crossover seals between chambers are a simple sweep in a true circle and seat in like traditional piston rings. Ring seals on each of the rotor plates seal the chamber sides similar to the Wankel’s rotor side seals.

The housing plates supporting the sun gears act as the lubrication inlet and outlet paths to and thru the main crank. The main crank transmits lubrication into the rotor and its mini-crank bearings and pivot piston pins. The mini-cranks transmit lubrication to the rod bearings.

The engine is naturally well balanced. The only reciprocating parts are the pivot pistons and connecting rods that are counterbalanced opposite to each other. With all four strokes for all chambers completed in one revolution the smoothness will also be enhanced.